3 Key Benefits of Using Closed Cell Foam Tape

Leave a Comment Closed cell foam tape is useful in a number of applications. Its unique structure doesn’t allow air, fluids, or solid particles to pass through, making it effective for soundproofing, protective packaging, sealing and padding face shields and masks, and more. It serves its purpose as a measure of safety as well as comfort in certain applications.

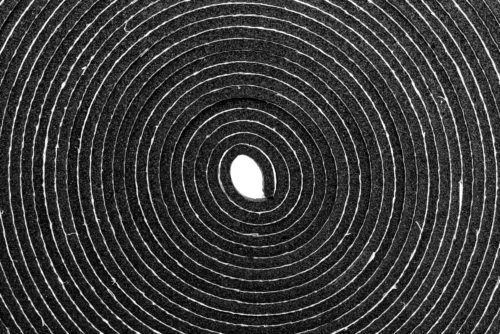

Closed cell foam tape is useful in a number of applications. Its unique structure doesn’t allow air, fluids, or solid particles to pass through, making it effective for soundproofing, protective packaging, sealing and padding face shields and masks, and more. It serves its purpose as a measure of safety as well as comfort in certain applications.

This foam tape can be made from polyethylene, neoprene, PVC, nitrile foam rubber, EVA, or SBR foam rubber. The density of these materials gives them stronger resistance to moisture and air, which makes them cost-effective in the long run despite a potentially higher upfront cost. Below, our team at NADCO delves into the top advantages for using this kind of tape.

1. Closed Cell Foam Tape Is Cost Effective

Even though the materials themselves may cost more than less durable alternatives, closed cell foam tapes can be formed and cut with extreme precision, which limits waste and reduces materials costs. Precise measurements allow us to deliver large rolls of tape while reducing overhead costs to keep your initial investment as low as possible.

Even though the materials themselves may cost more than less durable alternatives, closed cell foam tapes can be formed and cut with extreme precision, which limits waste and reduces materials costs. Precise measurements allow us to deliver large rolls of tape while reducing overhead costs to keep your initial investment as low as possible.

Over time, the value of using a high-quality closed cell foam tape becomes even more apparent. It’s effective over a long life span, and you’ll be spending less money on repairs and replacements in the future.

2. Closed Cell Foam Tape Is Moisture Resistant

While open cell foam tapes are lightweight and flexible—which is appropriate for a number of applications—they don’t block fluids the way closed cell foam tapes do. That makes the closed cell version the industrial tape of choice for any application where moisture resistance is important, including in the HVAC, automotive, medical, construction, and marine industries.

While open cell foam tapes are lightweight and flexible—which is appropriate for a number of applications—they don’t block fluids the way closed cell foam tapes do. That makes the closed cell version the industrial tape of choice for any application where moisture resistance is important, including in the HVAC, automotive, medical, construction, and marine industries.

With densities around two to three pounds per cubic foot range, closed cell materials are durable and tough. You can choose an adhesive that’s resistant to UV light and corrosion while offering protection against vibration, dust, and more. These tapes are often used for sealing gaps (around windows and doors, for example), protective packaging, gasketing, and shock absorption, as well as waterproofing.

3. Closed Cell Foam Tape Is Flexible & Adaptable

This high-density foam tape is made for environments that demand adaptability along with reliability. Despite its ability to expand and contract with changes in temperature and pressure, closed cell foam tape continues to hold its bond. This is a huge advantage over more traditional fastening options, since the majority of those will eventually loosen after repeated expansion and contraction. It’s a go-to solution in environments that experience extreme or frequent temperature changes.

This high-density foam tape is made for environments that demand adaptability along with reliability. Despite its ability to expand and contract with changes in temperature and pressure, closed cell foam tape continues to hold its bond. This is a huge advantage over more traditional fastening options, since the majority of those will eventually loosen after repeated expansion and contraction. It’s a go-to solution in environments that experience extreme or frequent temperature changes.

Closed cell foam tape is easily customizable as well. From double-sided adhesive to resistant linings and specialized materials, your tape can be created specifically to meet your unique needs.

Learn More About Closed Cell Foam Tape

NADCO is a custom manufacturer of closed cell foam tape and a variety of other adhesive tapes and labels for use in a number of industries and applications. With nearly 30 years of experience and a 35,000-square-foot facility, we’re equipped to handle orders of all sizes and complexities.

The three key benefits (and so many potential uses) of closed cell foam tape mean it’s always in demand, perhaps now more than ever with the increased need for personal protective equipment. Contact us to discover more about the benefits of adhesive foam tape, custom PPE, and more.