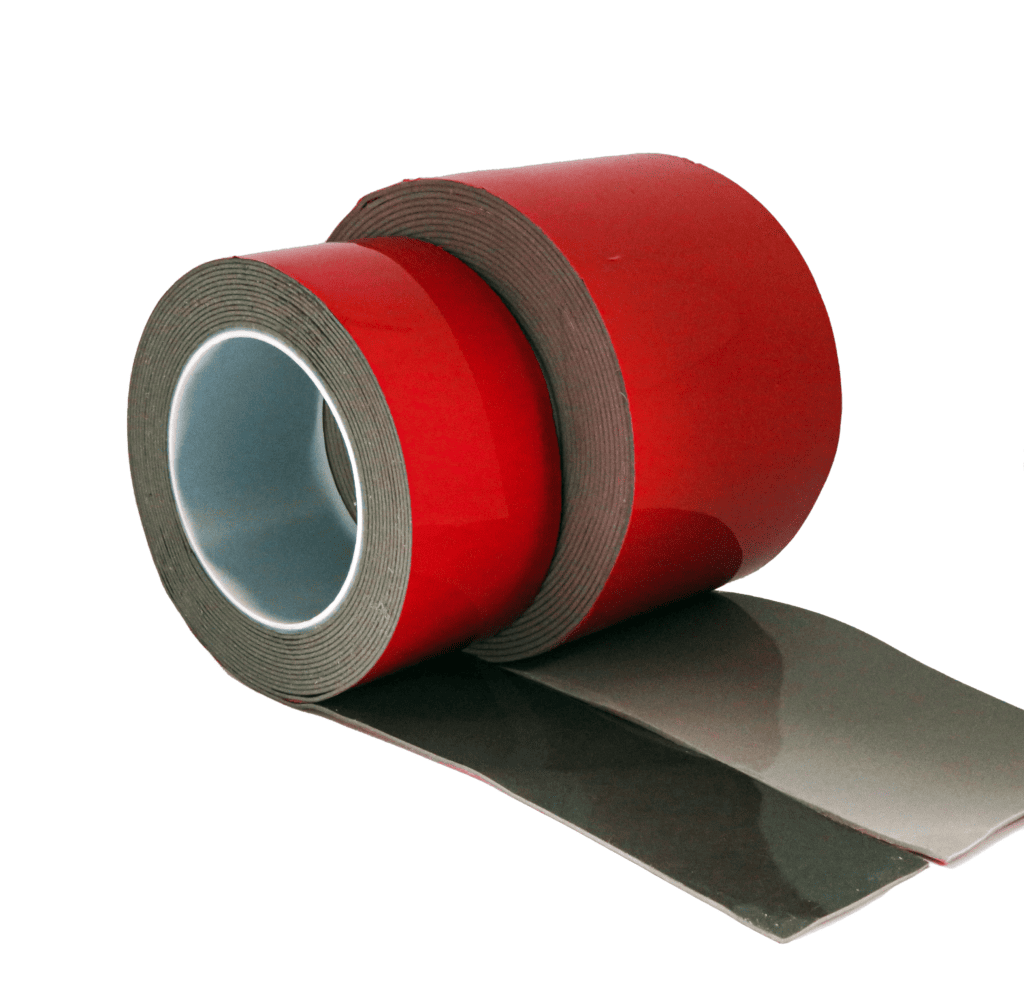

UHB Tapes & VHB Tapes

Ultra-high bonding (UHB) tapes and very-high bonding (VHB) tapes are solutions for applications that require powerful adhesion and nearly indestructible bond strength. Both of these products are compatible with a wide range of substrates, including metal and plastic materials, and achieve maximum bond strength 72 hours after application. Whether you’re looking for UHB tapes or VHB tapes, NADCO has a high-performing product that will meet the needs of your application.

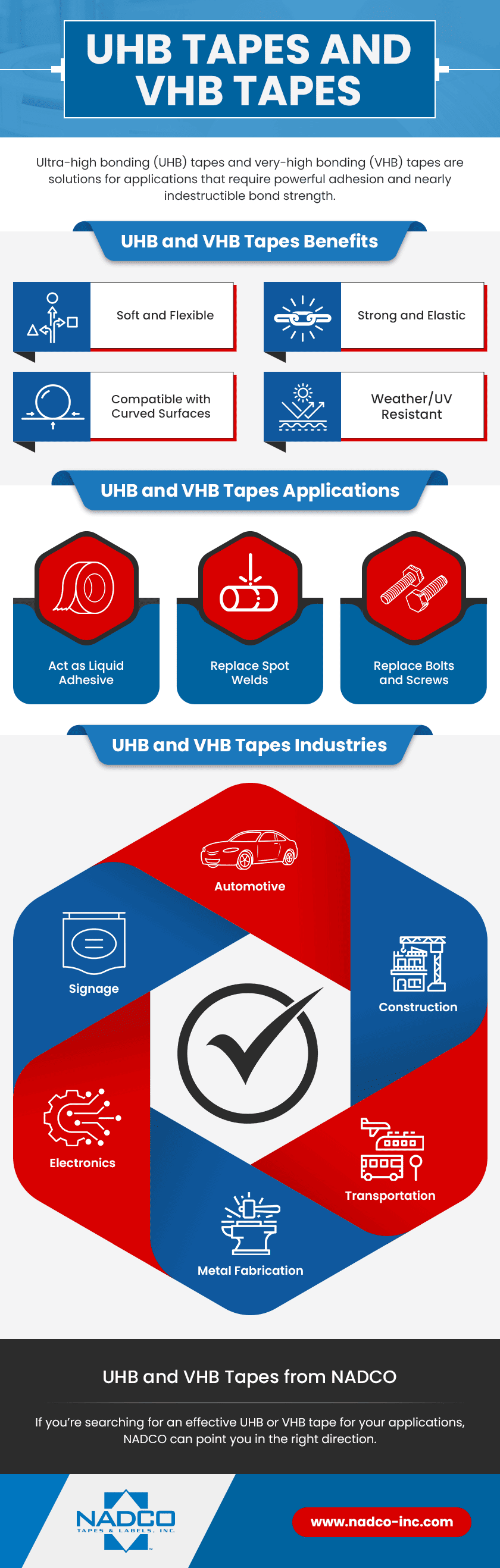

UHB and VHB Tape Benefits

UHB and VHB tape is soft and flexible in nature, which allows it to easily conform to uneven surfaces. Since it is made using acrylic foam, it also has good elasticity due to its internal cohesive strength. It is highly compatible with round or curved surfaces and provides a more beneficial alternative to spot welding. This type of tape is stronger than construction-grade bonding materials and, unlike processes such as welding, will not distort sheet metal or create welding beads that would require secondary processing. It is commonly used in place of metal fasteners, eliminating the possibility of warping or sealant leakage caused by fasteners and gaskets.

UHB and VHB tapes are highly durable and weather resistant. In fact, most varieties can withstand extreme temperatures, solvents, moisture, UV light, and more. In addition, they enhance the durability of the end product by preventing bi-metal corrosion.

To learn more about VHB tapes and their industry-specific uses, read our product brochure.

UHB and VHB Tape Industries Served & Use Cases

UHB and VHB tapes deliver exceptional bond strength and long-lasting durability in a diverse range of applications. They distribute stress over a substrate’s entire surface and absorb the shock caused by wind, vibrations, and other stresses. Both of these tapes are used to replace spot welds, rivets, screws, and liquid adhesives, eliminating dimpling and distortions. The following are some industry-specific uses for UHB and VHB tapes.

UHB and VHB tapes deliver exceptional bond strength and long-lasting durability in a diverse range of applications. They distribute stress over a substrate’s entire surface and absorb the shock caused by wind, vibrations, and other stresses. Both of these tapes are used to replace spot welds, rivets, screws, and liquid adhesives, eliminating dimpling and distortions. The following are some industry-specific uses for UHB and VHB tapes.

Automotive

The automotive industry uses UHB tapes for joining surfaces, hanging signage, mounting components, and more. It is frequently used in place of rivets, bolts, screws, and spot welds. VHB tapes create an immediate bond strength that increases to its maximum strength over the next 72 hours. In automotive applications, they dampen vibrations and noise to create a quieter ride. They also attach graphics and advertisements smoothly and separate metals to reduce the likelihood of corrosion.

Construction

Both UHB and VHB tapes are effective replacements for mechanical fasteners and liquid adhesives in construction applications. They can both be applied to flat or curved surfaces. VHB tapes are used to bond primed wood, painted aluminum, or vinyl to glass windows or doors. They also attach stainless steel wall panels to a building’s frame. UHB tapes are used to create skylights, elevator interiors, climate control ceilings, mount store signage, and more.

Transportation

The transportation industry uses UHB and VHB tapes for their resistance to extreme temperatures, vibrations, moisture, and UV light. They can be used to attach rear-view mirrors and emblems, apply roof rails and wheel arch trim, fix bumpers and antennas, and more.

Metal Fabrication

Tapes are an easier assembly method than riveting and welding and still create a long-lasting bond. UHB and VHB tapes are compatible with bare and painted metal surfaces and, unlike metal fasteners, show no visible signs of stress under stress conditions.

Electronics

UHB and VHB tapes offer flexibility and precision in electronics-related applications. They can be die-cut to the exact shape needed and easily withstand process heat. Tapes can be used to mount LCD display panels to metal frameworks, bond screens to high-definition televisions, and assemble many other types of electronic and electrical devices.

Signage

UHB and VHB tapes are strong enough to hold signs reliably, even in challenging weather conditions. Unlike metal fasteners, they remain hidden from sight and don’t create holes where corrosion could occur. Using tapes to mount signage doesn’t require highly skilled labor and is suitable for numerous applications, such as bonding illuminated signs, fixing individual letters, attaching large panels, bonding digital sign frames, and much more.

VHB & UHB Tapes from NADCO

If you’re searching for the most effective UHB tape or VHB tape for your application, NADCO can help you identify the right product. We offer an extensive range of standard and customizable tapes, labels, and adhesive products. No matter what challenges your application involves, we have a solution for you.

If you can’t find the product you’re looking for on our products page, we can help you develop a custom-printed solution. If you can imagine it, we will make it stick. To learn more, contact our team with any questions or request a quote.