Foam Tape

Foam tape is an adhesive tape reinforced with a variety of foam materials. A variety of thicknesses, sizes, adhesive materials, and backings make each foam tape design unique, offering distinct properties depending on the application. A product with so many potential uses, foam tapes provide insulation, cushioning, and sealing, sound dampening, and gasketing. Versatile foam tapes deliver on enhancing and improving the overall design and performance of any product.

NADCO® Tapes & Labels, Inc. offers the best in foam tapes for any application, no matter if for the aerospace, automotive, or medical industries.

— VIEW OUR PRODUCT CATALOG —

Materials Used in Foam Tapes

Typically, foam tape consists of either polyethylene (polyfoam) or polyvinyl chloride (PVC). However, foam tape made of alternative materials may suit different applications. Foam tape configurations can be divided into open cell and closed cell foam structures.

Open Cell Foam

In an open cell foam configuration, the cell form allows air, solid particles, and water to pass through the foam material because of its high porosity. Typically composed of EPDM rubber, polyurethane, PVC, and nitrile, these foams tend to be more lightweight compared to other foams, weighing only about ½ to ¾ pounds per cubic foot. These foam types prove easier for packaging and transportation because of their low density and high expansion and contraction capacity. Though this open cell foam provides excellent soundproofing characteristics, it also has the capability of trapping particulate matter such as dust and a resistance to molds.

In an open cell foam configuration, the cell form allows air, solid particles, and water to pass through the foam material because of its high porosity. Typically composed of EPDM rubber, polyurethane, PVC, and nitrile, these foams tend to be more lightweight compared to other foams, weighing only about ½ to ¾ pounds per cubic foot. These foam types prove easier for packaging and transportation because of their low density and high expansion and contraction capacity. Though this open cell foam provides excellent soundproofing characteristics, it also has the capability of trapping particulate matter such as dust and a resistance to molds.

Closed Cell Foam

Conversely, closed cell foam structure prevents the passage of anything through the tape, including air, fine solid particles, and liquids. Materials used for closed cell foam include polyethylene, EVA, neoprene, PVC, nitrile foam rubber, and SBR foam rubber. Though they may have higher costs initially, these foams have a higher density which makes them better resistant to moisture and air, making them cost-effective in the long-run. With these positive qualities, they serve purposes such as in protective packaging and soundproofing applications.

Conversely, closed cell foam structure prevents the passage of anything through the tape, including air, fine solid particles, and liquids. Materials used for closed cell foam include polyethylene, EVA, neoprene, PVC, nitrile foam rubber, and SBR foam rubber. Though they may have higher costs initially, these foams have a higher density which makes them better resistant to moisture and air, making them cost-effective in the long-run. With these positive qualities, they serve purposes such as in protective packaging and soundproofing applications.

Key Benefits of Foam Tape

Extremely adaptable, foam tape allows for endless customization, catering to the demands of nearly any application. Using foam tape yields numerous benefits, including both time- and cost-effectiveness, extended service life, as well as adaptability and flexibility.

Time Saving

Utilized as an interior adhesive in devices and equipment, foam tape eliminates the need for fasteners, liners, and sealing materials. With less time spent on installation and waste management, this product can significantly reduce overall manufacturing labor and time requirements, leading to an increase in efficiency in production.

Material Cost Reduction

Easy and inexpensive to manufacture and form within precise dimensions, foam tapes can minimize your material cost. Tape conversions processes like lathe splitting and die cutting allow us to meet the exact requirements required by your project. With precision in measurements, we deliver large rolls or logs but still keep down the overhead cost for the materials.

Extended Service Life

Exceptionally durable, foam tapes retain their properties in a variety of adverse conditions. Most notably, the PVC foam tape resists damage from solvents, chemicals, fuels, flames, and UV rays. As a closed cell configuration, PVC foam resists moisture absorption, making it unlikely to rot. PVC resists vibration, and it also offers an excellent fatigue life. PVC foam’s resistance to these many elements make it a practical choice for longevity, especially considering this material also maintains compatibility with other adhesives and resins.

Flexible and Adaptable

Foam tapes expand and contract due to temperature and pressure changes, but still they retain a reliable bond. More traditional fasteners will loosen when forced to repeatedly expand and contract. Made to adapt, foam tapes flex with thermal expansion, and contract to hold their bond. They are customizable to meet the needs of any particular applications, and they can utilize designs with double sided adhesive, resistant linings, and specialized materials.

— VIEW OUR PRODUCT CATALOG —

Industries That Use Foam Tape

A wide range of industries rely on the versatility and utility of foam tape. Across these various industries, foam tape applications can include:

A wide range of industries rely on the versatility and utility of foam tape. Across these various industries, foam tape applications can include:

- Aerospace equipment

- Automotive components

- HVAC arrays

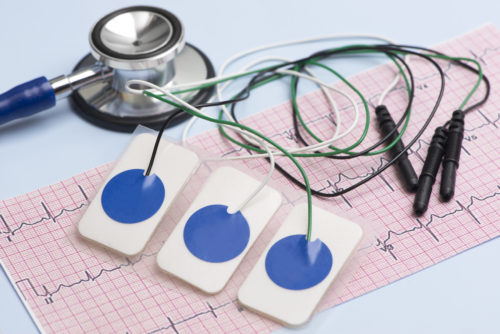

- Medical devices and equipment

- Outdoor applications

- Construction and architecture

Particularly useful in the medical industry, foam tapes enhance infectious disease containment (IDC) equipment. They can be used to seal, insulate, and pad everything from face masks to splash guards. In fact, recommendations call for personal protective equipment (PPE) to be lined with foam tape in order to form an efficient seal to prevent contamination from bodily fluids and infectious agents.

As technology advances, foam tape demand will increase, with projections estimating it may grow into a $10.3 billion market. More and more, manufacturers see the value of foam tape in enhancing their products and reducing overhead. Its exceptional usefulness, customizability, durability, and unique sealing properties make foam tape an efficient and economical fastening and sealing option.

Quality Foam Tapes From NADCO

NADCO Tapes & Labels, Inc. is a dedicated provider of tapes and label products for customers in a wide range of industries, from aerospace and automotive to medical applications. We are dedicated to providing the highest quality tapes in the industry, and our 35,000 foot facility allows us to manufacture and stock a comprehensive selection of tapes and labels to meet our customers’ every need. Our customization services are second to none, and our dedicated team of engineers and specialists are happy to assist you with the design and manufacture of specialized foam tapes tailored to your particular application.

Our dedicated design engineering team looks forward to finding the foam tape solution best for you. In our impressive 35,000 square-foot facility, we proudly manufacture and stock a comprehensive selection of tapes and labels to meet every individual customer’s need.

In addition to our superior foam tapes, we offer:

- Vinyl, film, cloth, paper, and duct tapes

- Metal foils

- Specialized high-performance products

- Double-coated products

- Pipe markers, symbols, dots, and arrows

- Safety products

To learn more about NADCO’s superior foam tapes and other adhesive solutions, contact us today.