Foil Tape

In outdoor environments, materials are often regularly exposed to harsh conditions, such as temperature extremes, high moisture or humidity, corrosive or abrasive chemicals, and ultraviolet rays. As such, the adhesive tapes employed for attachment purposes should be capable of withstanding exposure to the above conditions, among others. Foil tapes are highly durable and demonstrate many of the above requirements, making them an ideal solution for such applications.

— VIEW OUR PRODUCT CATALOG —

What Is Foil Tape?

First introduced into the market in 1888 and commercially produced in 1913, foil tape was used by the military for insulation, packages, and electrical components during World War II. Afterward, it began finding widespread use in commercial applications due to its durability, flame retardance, and resistance to chemicals, extreme temperatures, humidity, and UV radiation.

All foil tapes consist of two key components: metal foil and adhesive backing. The foil material is what gives the tape its characteristic shine, malleability, conductivity, and ruggedness, while the adhesive backing allows it to stick to other substrates. As these tapes find application in many industrial environments, they are available in several variations to suit different requirements and restrictions.

Types of Foil Tapes

Foil tapes vary in regard to the metal foil and/or adhesive backing employed. Some of the most common metal foils used for the manufacture of foil tapes are:

Foil tapes vary in regard to the metal foil and/or adhesive backing employed. Some of the most common metal foils used for the manufacture of foil tapes are:

- Aluminum. Aluminum foil tapes are highly conformable to irregular surfaces and provide a barrier against vapor. They are often used for the joints and seams of aluminum backed duct board and fiberglass and shielding and covering thermal insulation.

- Copper. Copper foil tapes are available in conductive or non-conductive and lined or unlined variations. They are chemically resistant and suitable for use as cable wrapping, electrostatic shielding, and materials for stained glass work.

- Lead. Lead foil tapes are generally employed as masking during chemical milling, electroplating, or X-ray operations. They can also be used as moisture barrier materials when sealing windows.

- Stainless steel. Stainless steel foil tapes are ideal for applications that require high adhesive strength, UV resistance, reflectivity, and thermal conductivity. They usually come with an adhesive strong enough to stick to bends, curves, and uneven surfaces.

Industrial Applications of Foil Tapes

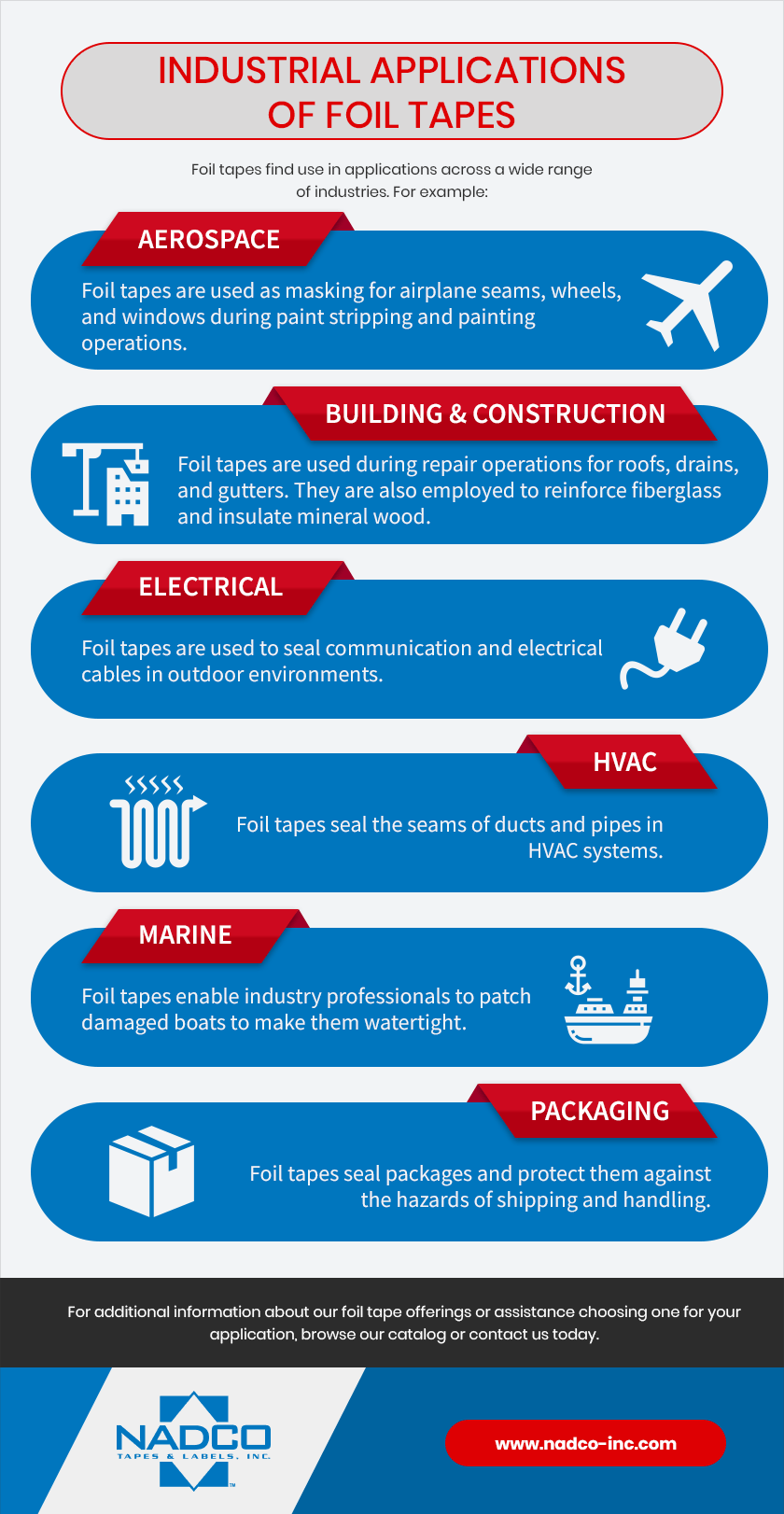

Foil tapes find use in applications across a wide range of industries. For example:

- In the aerospace industry: Foil tapes are used as masking for airplane seams, wheels, and windows during paint stripping and painting operations.

- In the building and construction industry: Foil tapes are used during repair operations for roofs, drains, and gutters. They are also employed to reinforce fiberglass and insulate mineral wood.

- In the electrical industry: Foil tapes are used to seal communication and electrical cables in outdoor environments.

- In the HVAC industry: Foil tapes seal the seams of ducts and pipes in HVAC systems.

- In the marine industry: Foil tapes enable industry professionals to patch damaged boats to make them watertight.

- In the packaging industry: Foil tapes seal packages and protect them against the hazards of shipping and handling.

— VIEW OUR PRODUCT CATALOG —

Foil Tapes From NADCO

NADCO® Tapes & Labels, Inc. has specialized in supplying tapes and other adhesive products for nearly three decades. Equipped with this extensive industry experience, our team has the knowledge and skills to help you with any adhesive need, including with regard to foil tapes.

NADCO® Tapes & Labels, Inc. has specialized in supplying tapes and other adhesive products for nearly three decades. Equipped with this extensive industry experience, our team has the knowledge and skills to help you with any adhesive need, including with regard to foil tapes.

For additional information about our foil tape offerings or assistance choosing one for your application, browse our catalog or contact us today.