Label Customization Options

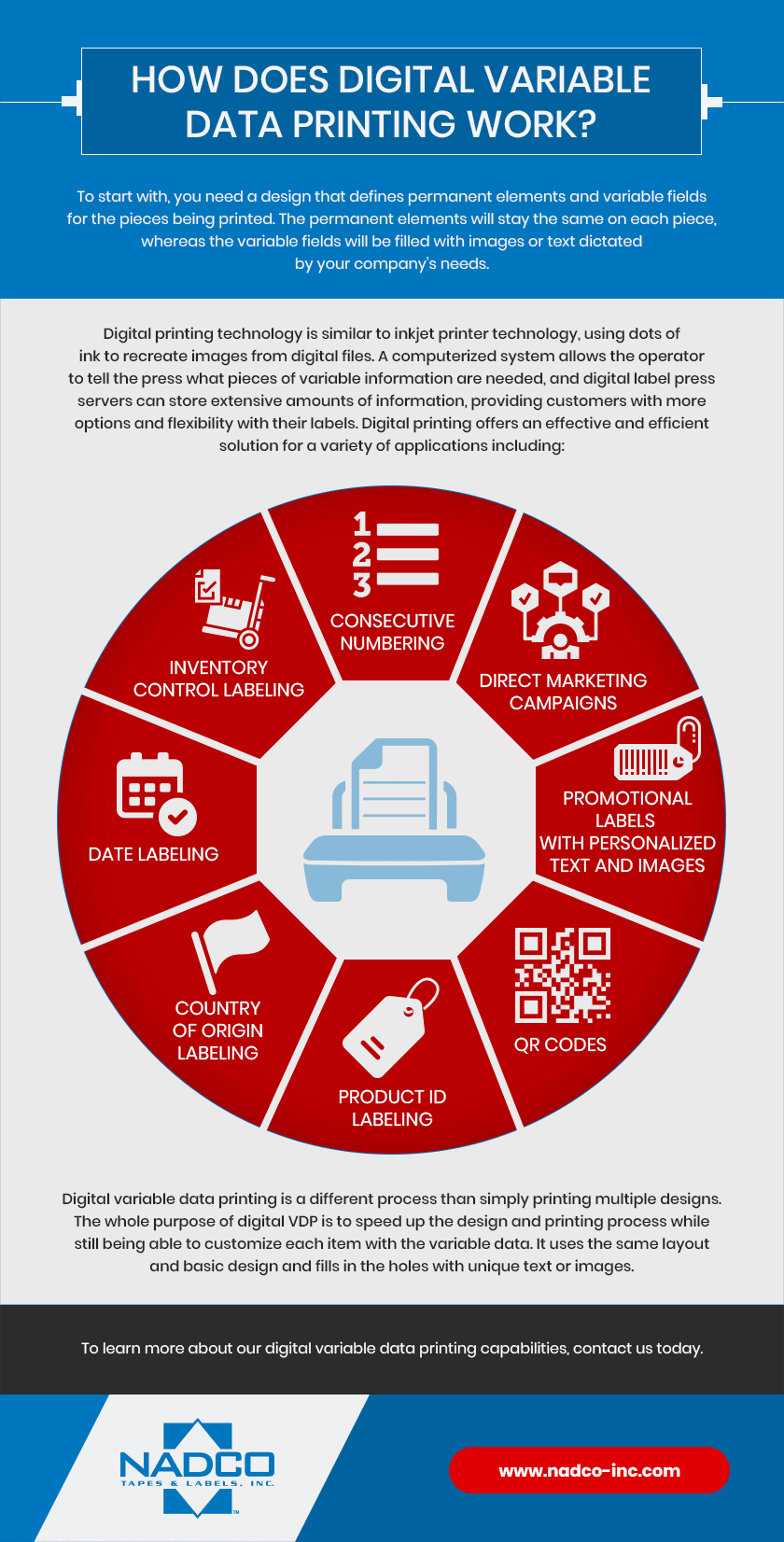

We offer a range of customization options with our variable image label printing services. We can produce barcodes and sequential numbering on any of our tape or label products – simply provide us with the necessary number range. It is also possible to generate repeating number patterns, such as 5, 10, 15, 20, etc., without a CSV file when customers identify the desired number pattern and supply the stop and start numbers.

However, some customization options do require the use of CSV files. Customers can create an Excel spreadsheet saved as a CSV UTF-8 (comma delimited) with a .CSV file extension. In these situations, such as in the example below, the file must include the changing records saved in individual cells and columns.

One label can accommodate several areas of variable data and customization. For example, if a customer requires a labeling solution that combines sequential numbering, personal images and barcodes, we can do that. Customers can also change background colors and images in two ways: sending a CSV file or using our stock seed files (graphic files with various repeating colors and patterns). Using our software, we can flip, rotate, reduce, or enlarge these files to produce unlimited variations. Additionally, we can change the color schemes to meet customer requirements, such as changing pastels to primary colors.

If you have questions on whether you need to provide us with a CSV or not, contact us and we will be happy to help.