The Top 5 Benefits of Pressure Sensitive Labels

Leave a Comment

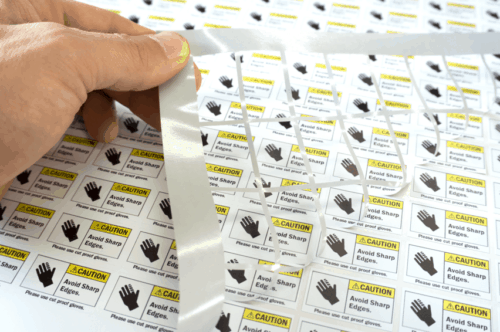

Pressure-sensitive labels (PSLs) consist of sheets or films coated on one side with an adhesive substance that is activated by pressure. These labels offer an advantage over other types as the pressure-sensitive adhesive does not require exposure to water or a solvent, allowing for quicker and easier application to a wide range of surfaces.

Due to the simplicity and versatility of their design, pressure-sensitive labels find use in a variety of consumer and retail applications, including on bottles, cans, jars, tapes, and electronic products. Selecting and using pressure-sensitive labels for your product(s) offers you a host of benefits. The top five benefits are:

#1 – Convenience

Pressure-sensitive labels withstand and maintain their integrity in a variety of environmental conditions, such as heat, cold, humid, wet, and dry environments. This quality makes them very attractive to producers that are looking for both ease of application and reliability.

The pre-application of adhesive on pressure-sensitive labels reduces the number of steps required for the labels’ application. As they don’t need the application of heat or exposure to a solvent to work effectively, they are also more readily and easily placed and applied on objects, including ones that do not respond well to heat or solvents.

Moreover, depending on the requirements of their application, different adhesives can be used to manufacture the pressure-sensitive label, allowing for permanent or temporary label application.

#2 – Ease of Use

Pressure-sensitive labels can adhere to virtually any material surface, including:

- Polyolefin-based

- Rubberized

- Dusty or contaminated

- Rough surfaces

- Humid or wet

Once their functionality or usefulness has played out, pressure-sensitive labels offer the additional benefit of being easily disposable as they contain minimal amounts of volatile compounds.

#3 – Wide Options to Choose From

Pressure-sensitive labels are available with a wide selection of customization options.

Adhesive Options

Depending on the requirements for the end product, the labels are applied with a variety of adhesives, including ones that that are:

- Permanent, semi-temporary, or temporary

- Heat or cold resistant

- Moisture resistant

- Anti-microbial

Substrate Material Options

Substrate Material Options

The substrate layer of the label is also available in a number of different materials, including:

Design Options

Once the substrate and adhesive substances are chosen, the finished pressure-sensitive label can also be fully customized with colors, patterns, textures, and designs, such as:

- Clear

- Metallic

- Glossy

- Matte

- Textured

- Wood grain

- Custom graphics and artwork

Overall, these labels provide a high level of customization in both their functional and aesthetic properties, making them suitable for consumer industries, including the beauty and cosmetics market.

#4 – Environmentally Friendly

Pressure-sensitive labels are more eco-friendly than other labels that require separate adhesive or solvent application. Compared to solvent-based labels, PSLs have minimal amounts of volatile compounds which can have adverse effects on the environment, and, compared to water-based labels, they require water to manufacture.

Pressure-sensitive labels are more eco-friendly than other labels that require separate adhesive or solvent application. Compared to solvent-based labels, PSLs have minimal amounts of volatile compounds which can have adverse effects on the environment, and, compared to water-based labels, they require water to manufacture.

#5 – Profitability

Pressure-sensitive labels provide manufacturers with an effective and economical solution for their labeling applications. The versatility and ease of use of these labels make them suitable for a broader range of manufactured products, minimizing the number of different labels required in inventory for everyday operations.

Customized pressure-sensitive labels are available at low costs with a variety of options for the adhesive, substrate, and design. Generally, customization of these labels results in high quality rendered products suitable for use in consumer and retail applications.

Additionally, as the adhesive is already on the label, less time is required for applying adhesive or activators, changing labels, and cleaning up spilled substances. By optimizing these label application operations, facilities experience improved overall productivity and, consequently, profitability.

Partner with NADCO for Your Label Needs

At NADCO Tapes & Labels, Inc., we are an industry leader in the production of custom printed pressure-sensitive labels suitable for countless industrial and commercial applications, including:

- Product identification

- Branding

- Decoration

- Safety and information

We offer several different printing methods that can be tailored to meet your project requirements. These methods include:

- Flexographic printing

- 4-color processing

- Spot printing (up to 7 colors)

- Short-run digital printing

Request a Quote today to learn more about how NADCO can meet and exceed the expectations of your next project! Our pressure-sensitive labels provide the functional and aesthetic qualities required for your products.