The Integral Role of Tapes and Adhesives in Fighting COVID-19

COVID-19 has necessitated implementing defensive strategies to keep not only ourselves but also others as safe as possible. One of the most essential preventive tactics is social distancing. Reducing airborne contamination is one of the keys to stopping the spread of coronavirus. However, it can be hard to visually judge safe distances and learn new habits without guidance.

Directional flow tapes are one way to help the public learn safe distances to prevent the spread of infection. Social distancing decals for COVID-19 can be used to mark spots to wait in lines and indicate entry and exit points. They are meant to be easily seen when placed on floors and allow safe, unimpeded movement with appropriate distancing.

How Tapes and Adhesives Have Helped During COVID-19

As the world tries to contain the spread of the virus, manufacturers have rallied to shift production to meet the emerging needs. Several innovative tape and adhesive products have been developed, which give retailers and essential businesses a way to provide goods and services while protecting their customers.

Social Distancing Tapes

Low-profile, brightly colored social distancing tape offers much-needed guidance when measured proximity is critical. It allows customers to see where the traffic pattern should flow as well as where to wait to maintain the recommended six-foot distances between others. The colors are eye-catching, and hazard stripes are a universal warning sign that doesn’t require wording to be understood. Businesses can customize the messaging to give more instruction for safe distancing.

Packaging/Shipping Products During COVID-19

There have been many shortages during the pandemic due to illness, stay-at-home orders, and the redistribution of materials used in critical personal protective equipment and medical supplies, including acrylic packing supplies. Shipping is more critical than ever for everything from household products to food to medical supplies. Hot melt tapes are helping to bridge the gap to make sure that packages stay sealed for sanitation and safety.

PPE/Construction Assembly

Many frontline workers and first responders are working without adequate protection, and specialty tapes and adhesives are needed to help supply the desperate PPE need. Unbroken seals must be maintained for protective devices to effectively prevent contamination and infection from entering between the soft materials and hard plastic. Tapes and adhesives are used to create clear face shields that prevent droplets from entering the eyes and mucous membranes. Depending on the type of material, they can also be used for other types of protective masks to provide a secure and comfortable fit.

Key Benefits to Using Tapes and Adhesives to Fight COVID-19

Keeping essential workers and the rest of the population safe in public settings while preventing the further spread of the pandemic is top of mind in every industry. From warehouses to production facilities, gas stations to supermarkets, and government offices to medical facilities, the need for guidance, education, and messaging is urgent where people must be in the same space. There are many advantages of using tapes and adhesives in the fight against coronavirus:

Keeping essential workers and the rest of the population safe in public settings while preventing the further spread of the pandemic is top of mind in every industry. From warehouses to production facilities, gas stations to supermarkets, and government offices to medical facilities, the need for guidance, education, and messaging is urgent where people must be in the same space. There are many advantages of using tapes and adhesives in the fight against coronavirus:

- They do not impede movement like physical barriers, yet the bright colors and markings are noticeable.

- Low profile means low risk of tripping or falling while still providing explicit instruction for maintaining a safe distance.

- They are an inexpensive way to provide signage and distancing guidance.

- They are removable when needs change.

- The messaging is customizable.

- Keeping people reminded of a safe six-foot social distance reduces the likelihood of transmission and eases the strain on the healthcare system.

Tapes and Adhesives From NADCO

NADCO is an industry-leading specialist in the design, manufacture, and delivery of custom pressure-sensitive tapes and labels. We create our tapes using both liner and over-lamination products to stand up to heat, high traffic, and harsh conditions. Our directional flow arrow tape meets all OSHA/ANSI requirements. We can customize any of our products to meet your specifications.

Let Us Help You With Your COVID-19 Tape and Adhesive Supplies

It is going to take diligence, commitment, and constant education to eradicate the risk of infection from COVID-19. When people have no choice but to be around others, they must have clear messaging and guidance for maintaining safe distances while traversing retail stores, medical offices, and workplaces. NADCO is committed to helping you by providing a cost-efficient, high-visibility way to guide pedestrian traffic in your facility.

We want to help make your workplace safer for you, your employees, and your customers. For more information about our products, contact us today.

Key Tips to Ensure Your Business is Social Distance Friendly

Businesses have always understood the importance of ensuring a safe environment for customers and employees, but in light of the pandemic, companies in all industries have new considerations when it comes to safety. Many have ramped up cleaning protocols and are doing their best to enforce social distancing, so they can continue to operate safely.

Businesses have always understood the importance of ensuring a safe environment for customers and employees, but in light of the pandemic, companies in all industries have new considerations when it comes to safety. Many have ramped up cleaning protocols and are doing their best to enforce social distancing, so they can continue to operate safely.

When it comes to social distancing for businesses, a simple way to help your customers and employees stay at least six feet apart is to mark the floor with tapes and adhesives and install instructional signage. You can outline the areas that are safe, highlight where to stand, indicate traffic flow directions, and more. In the age of COVID-19, adhesives are playing a big role in creating safe spaces.

Use Ground Marking Tapes for Social Distancing

Placing adhesives six feet apart on the ground where people tend to line up or congregate is a clear way to indicate where people should stand to maintain their distance. You’ll see these marks in retail stores, bank lines, gym floors, outdoor recreational areas, and more. Don’t leave it up to someone’s best guess about what it means to follow social distancing.

These ground-marking tapes are inexpensive and incredibly easy to apply. By choosing high-quality tapes with adequate resistance, you can expect your marks to last for months. 3M™ 471 vinyl strips are an excellent choice for many reasons, such as:

- They offer strong adhesion on many surfaces, including irregular surfaces.

- They’re resistant to water and abrasion for long-lasting use.

- They can be applied quickly and easily.

- They’re available in a wide range of colors to suit your space and application.

- They don’t leave residue when they’re removed.

Implement Directional Flow Tapes in Your Establishment

Without guidance, people are bound to cross or bump into each other at some point. Directional flow tapes allow you to establish traffic flow so everyone’s walking in the same direction, making it easier to maintain six feet of distance from the person in front of you.

You can use these arrows to indicate entrances and exits, the flow of traffic through the aisles, which stairs to take up and which to take down, and how to approach and leave a desk or counter.

Create Displays Using Tapes and Adhesives

Educational displays, like sandwich boards and freestanding signs and banners, can be created with tapes and adhesives and positioned at your business entrance, the service counter, or the restrooms. They’re ideal in any area where you’d like to remind people of social distancing guidelines or any special instructions that might be important at your facility. That could include information about capacity limits, foot traffic directions, hygiene guidelines, temperature-taking and health questionnaire protocols, and more.

Educational displays, like sandwich boards and freestanding signs and banners, can be created with tapes and adhesives and positioned at your business entrance, the service counter, or the restrooms. They’re ideal in any area where you’d like to remind people of social distancing guidelines or any special instructions that might be important at your facility. That could include information about capacity limits, foot traffic directions, hygiene guidelines, temperature-taking and health questionnaire protocols, and more.

You can offer the same information with adhesive signs on doors, walls, and windows. Whether you use standing displays, adhesive signs, or both may depend upon the layout of your building/room, how many people go through your building each day, and more.

Provide Protective Windows and Screens at Checkout

Many businesses are using transparent barriers as physical protection between customers and employees or between coworkers. This allows them to be as close as they need to be for financial exchanges or discussions and team projects without putting each other at risk.

These protective windows have to be assembled and carefully secured before use, and adhesives can help. Instead of using screws, clamps, or rivets, which are unsightly, take longer to install, and may make a mess, 3M VHB adhesives were created for this purpose. They’re strong enough to uphold these partitions. The viscoelastic acrylic adhesive is durable and temperature resistant; it’s designed to last, making it an ideal choice for permanent projects.

For over three decades, NADCO has been offering custom-printed tapes and labels for businesses all over the country. Our creative team can help you with product design as you order the adhesive solutions you need to maintain social distancing for businesses.

Contact us to learn more about our adhesive tape and label products and how we can serve your business.

Why You Should Use Directional Flow Tapes for Social Distancing

In the fight against the COVID-19 pandemic and other similar crises, one of the greatest defensive weapons is social distancing. The preventative strategy allows public figures and private citizens to help stop the spread of pathogens, reducing the number of affected people and, consequently, the strain on the healthcare system. While social isolation (i.e., completely isolating oneself from others) would likely be more effective than social distancing at minimizing and/or eliminating the rate of transmission, it is not a sustainable solution since day-to-day operations (e.g., working and food shopping) are still essential.

In essential businesses where contact with others is largely unavoidable (e.g., banks, grocery stores, and warehouses), many facility owners and managers are implementing social distancing measures to prevent unnecessary or excessive contact between people. For example, they are applying directional flow social distancing floor decals in their facility to help employees and customers abide by social distancing guidelines (i.e., a minimum of 6 feet where possible).

The following blog post provides an overview of directional flow tapes, outlining what they are, what benefits they offer social distancing applications, and what product capabilities are available at NADCO.

What Are Directional Flow Tapes?

As suggested by the name, directional flow tapes are tapes used to direct the flow of foot traffic. They generally feature a directional arrow and/or text (e.g., “ENTER”, “EXIT”, or “ONE WAY”). They are designed to be placed on the floor of the facility and positioned such that they point in the direction that traffic should proceed. For example, in grocery stores, they show customers where to enter, how to proceed through the store, and where to exit.

As suggested by the name, directional flow tapes are tapes used to direct the flow of foot traffic. They generally feature a directional arrow and/or text (e.g., “ENTER”, “EXIT”, or “ONE WAY”). They are designed to be placed on the floor of the facility and positioned such that they point in the direction that traffic should proceed. For example, in grocery stores, they show customers where to enter, how to proceed through the store, and where to exit.

Benefits of Using Directional Flow Tapes for Social Distancing Applications

The recent global outbreak of COVID-19 has led to an increase in the importance of directional flow tape. Its main functions are maintaining order and organization within a facility and marking out a clear path for customers, both of which help enforce social distancing by keeping foot traffic separate and in motion. When used properly, it can lead to lower transmission rates and safer conditions for employees and customers.

Directional Flow Tapes From NADCO

At NADCO® Tape & Labels, we specialize in the design, manufacture, and delivery of custom pressure-sensitive tapes and labels. Equipped with over three decades of industry experience and a state-of-the-art manufacturing facility, we have what it takes to produce adhesives tapes, labels, and other products for nearly any customer need. One of our core product offerings is directional flow arrow tape, which currently plays a critical role in the fight against COVID-19.

Our directional flow tape features an arrow that points in the direction of flow. It is made from a unique combination of liner and over-lamination materials that protect it against harsh facility conditions (e.g., heat and cold). Material options include aluminum, cloth, copper foil, foam, paper, polypropylene film, PVC film, and vinyl. It is also available in several standard colors and sizes (all of which comply with OSHA/ANSI requirements) and completely customizable to meet highly specific customer needs. While it is generally used on piping to indicate the flow of material, it can also be applied to facility floors to organize and control the flow of traffic for better compliance with social distancing guidelines.

Contact Us today to learn more about our directional flow tapes and how they can benefit your facility!

Duct Tape vs. Gaffer’s Tape; What’s the Difference?

Gaffer’s tape and duct tape are multi-purpose, pressure-sensitive adhesive materials, each with their own distinctions. Both gaffer’s tape and duct tape offer strong holding capabilities due to their fabric reinforcement design, but the best choice tape will depend on the intended application. Below is a guide to help you decide which one will work best for your specific project.

What Is Gaffer’s Tape?

Gaffer’s tape, also referred to as gaff tape, is a heavy-duty vinyl-coated, cotton pressure-sensitive tape that is often used in film production or for live shows. It’s very durable and does not wear down easily from foot traffic, which makes it an excellent choice for marking stage positions. Gaffer’s tape is non-reflective and usually keeps its shape better than duct tape. Its no-residue removal makes it ideal for situations when a temporary adhesive is needed. It also does not leave sticky adhesive on surfaces or cause damage, such as pulling paint off of walls.

What Is Duct Tape?

Duct tape is a polyethylene coated, cloth pressure-sensitive tape well known for its versatility and strength. It is coated with a polyethylene resin on one side and an aggressive, rubber-based adhesive on the other. Duct tape’s unique property of a cloth backing gives it its durability while still being able to be torn easily and applied to a variety of surfaces. It is also often recognized by its reflective, shiny finish.

Gaffer’s Tape vs. Duct Tape

Gaffer’s tape and duct tape are both used for a range of applications due to their versatility. However, there are some important differences to keep in mind when choosing the right tape for your project.

- Duct tape will leave behind a sticky residue when removed from an object or surface, whereas gaffer’s tape leaves the surfaces and items to which it is applied residue-free.

- Gaffer’s tape is more heat resistant than duct tape.

- Duct tape has a fabric strength backing.

- Gaffer’s tape is easily torn by hand, whereas some duct tape must be cut with scissors or knives.

- Duct tape is highly reflective, whereas gaffer’s tape has a low gloss or matte finish.

- Gaffer’s tape is best for temporary or removable adhesive solutions, whereas duct tape is best for permanent or semi-permanent solutions.

- Duct tape is less expensive than gaffer’s tape.

Industry Applications: Gaffer’s Tape vs. Duct Tape

Common Uses of Gaffer’s Tape

Gaffer’s tape is flexible enough to be used on almost any shape or surface, which makes it ideal for a variety of uses. It is a popular choice for the arts and entertainment industry and the following common uses:

- Position marking, often on a stage in a theater setting

- Managing cables in production studios

- Marking hazardous areas such as inclines, flights of stairs, etc.

- Repairing of bus seats

- Bookbinding

Common Uses of Duct Tape

Duct tape is used for many household fixes as well as:

- Vinyl repair

- Abrasion protection

- Bundling wire, metals, or plastics

- Color coding

- Quality waterproof packaging

- Splicing

- Ductwork sealing

- Seaming applications

NADCO Offers Both Gaffer’s Tape and Duct Tape

NADCO is known as a top-rated company for high-quality tapes and adhesives. We offer both gaffer’s tape and duct tape to help you in all your sticky situations.

Types of gaffer’s tape NADCO offers include:

- VCC 125 Premium Vinyl-Coated Cloth Gaffer Adhesive Tapes

- CGT-80 Gaffer Low Gloss Finish Adhesive Tapes

Types of duct tape include:

Although duct tape and gaffer’s tape have some similar features, they cannot be used interchangeably. Do you need help deciding on the best tape for your project?

Contact Us to help you choose the tape that will best fit your needs. Trust the tape experts at NADCO for high-quality tape and adhesives you can rely on.

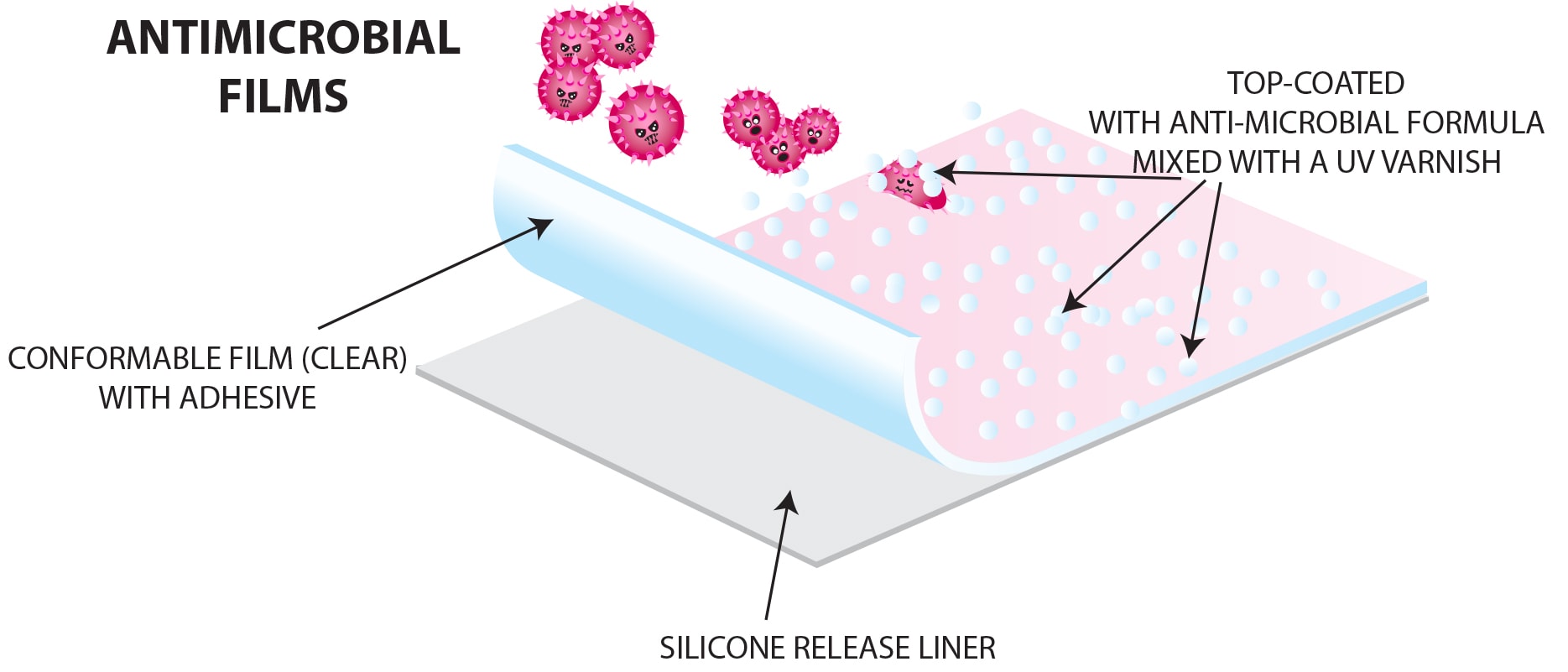

Antimicrobial Films for Front-line Workers

Antimicrobial film is used to protect workers and products from the spread of pathogenic contaminants such as bacteria, mildew, and fungi. The film incorporates a green-colored, high-gloss top coat that contains antimicrobial Agion technology.

Antimicrobial film is broadly used in medical facilities, food production, and service industry settings to improve customer safety, reduce the risk of microbial contamination, and enhance workplace cleanliness. It has been particularly useful for medical facilities during the COVID-19 outbreak, as it helps to prevent the spread of bacteria and other pathogens that can create additional complications in an already challenging situation.

What Is Antimicrobial Film?

Antimicrobial film is a 48 gauge PET plastic film coated in antimicrobial Agion material that can be added to the surface of a variety of materials. It is often applied to tapes and labels for safe and easy application to surfaces, and can also be used in food and medical packaging to protect products from mold and bacterial contamination.Agion is made up of silver ions and zeolite, for a safe and non-toxic antimicrobial coating that can be used for daily activities. The silver and zeolite combination interrupts cell metabolism, prevents cell multiplication, and inhibits the membrane transport process between cells, thereby preventing the growth and transmission of pathogenic contaminants.

Antimicrobial Film Applicationsantimicrobial films include:

- Common and Multi-Use Surfaces

- Tape and Label Coating

- Communal Building Materials

- Insulation Products

- HVAC Products

- Cleanrooms and Controlled Environments

- Medical Products, Packaging, and Facilities

- Household and Commercial Appliances

- Computer Touch Screens, Keyboards, and Switches

Industries That Can Use Antimicrobial Films

How Antimicrobial Films Can Help COVID-19 Frontline Workers

Reliable Antimicrobial Films by NADCO

Antimicrobial films have a broad range of uses in a variety of industries. At NADCO, we are pleased to offer antimicrobial coatings for tape, labels, and other adhesive products. We have extensive experience in the manufacture of high quality industrial labels, safety decals, and customized stickers for many industries and applications. Our state-of-the-art facility allows us to create custom designed adhesive products to meet our customers’ specialized needs. All of our designs are handled in-house, and our experienced and knowledgeable designers work directly with clients to develop solutions that meet their specifications.At NADCO, we understand that time is of the essence in today’s world, especially for our customers working on the front lines of the pandemic. Our full service manufacturing facilities ensure that we can design and produce your product with the utmost speed and efficiency. With our in-house production, you know that you can depend on a quality product straight from the source.

Contact Us today to learn more about NADCO’s antimicrobial film and adhesive solutions!

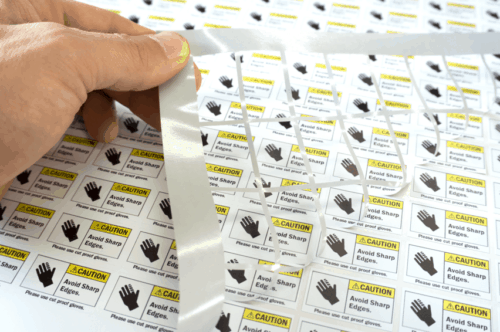

Why You Should be Utilizing Tamper-Evident Labels

Tamper-evident labels show signs when someone has tried to open or tamper with a product. These labels or seals contain features that make it impossible to remove or peel up the material without damaging it in an obvious way. Effective tamper-evident labels must not separate easily from the product’s container and are often designed to split or separate after any attempt to remove them.

The FDA requires these labels to have a distinctive design and composition so that consumers know that the label they see is real and not a duplicate replacement. “Distinctive” may refer to what’s printed on the label, the material the label is made of (something that can’t be copied easily by whoever is trying to alter the product), and the features that leave visible evidence that the label has been breached.

Use Tamper-Evident Labels for Security and Safety

The need for tamper-evident labels arose for a variety of reasons, but most importantly to ensure the safety and security of products when they reach the end user. Whether the product is food, medication, or a piece of equipment, buyers want to be sure that what’s in the box is what was packed in the box.

Tamper-evident labels can’t be opened and then replaced. They leave visual evidence for the end user to see. Tamper-evident labels may use a variety of methods, such as:

- A printed message that sticks to the product when the label is removed, such as “void”

- A pre-cut slit in the label that tears when attempting to remove the label

- Fragile films that are guaranteed to tear because they can’t be removed in one piece

When it is impossible to alter the label without a clear sign, it becomes exceedingly difficult to tamper with the products inside of a package. An intact tamper-evident label shows the customer that your product is safe to use or consume, while any damage immediately tells the customer not to use the product and report the damaged label to the store or manufacturer.

Tamper-Evident Labels Maintain Brand Integrity

Tamper-evident labels ultimately help companies to preserve the integrity of their brands. Given that tamper-evident labels are difficult to manufacture and custom brand designs are even more difficult to reproduce, these labels ensure that counterfeiters or other brands cannot duplicate your label. Your brand will eventually become known for its strong, tamper-evident labeling and repeat customers will come to appreciate this verification of the integrity of the products they purchase from you.

Common Uses for Tamper-Evident Seals

Some of the most common uses for tamper-evident labels are in the food, beverage, and pharmaceutical industries. Tampering with these products leads to food safety violations and potential danger, not to mention an economic loss if the customer doesn’t receive all of what they paid for.

Potential use cases include:

- Pharmacy/pharmaceutical. With an increase in the popularity of pharmacy deliveries and online pharmacies, tamper-evident medication labels help to verify product integrity and patient safety.

- Restaurant delivery. With the rise of food delivery apps, food delivered from restaurants to customers has more touch points than ever before. A tamper-evident label ensures that food remains fresh and tamper-free in the hands of third-party deliverers.

- Grocery delivery. Online grocery delivery is exploding in popularity. Tamper-evident labels on bags and cartons helps to ensure the integrity of items from packing to final delivery.

- Critical shipments. Tamper-evident labels provide a simple, yet effective means of ensuring the integrity of high-value parcel shipments as they move through the various steps of the supply chain.

- Laundry soap. Many laundry soap manufacturers are turning to tamper-evident labels to make sure distributors or retailers don’t water down or otherwise alter their products.

Tamper-Evident Labels From NADCO

Tamper-evident labels and seals offer and a simple and effective means of securing products. NADCO can help you keep your products safe and secure with our void tapes and other tamper-evident products.

Contact Us or Request a Quote today for more information about our tamper-evident solutions or other products!

Open Cell vs. Closed Cell Tape: What’s the Difference?

Foam tapes are available in a variety of carriers, sizes, thicknesses, and adhesives to suit a variety of product needs. Additionally, foam tapes withstand temperatures from -40° F to 300°F since their high bonding strength makes up for dissimilar thermal contractions and expansions. They hold up well against moisture, chemical solvents and exposure to the sun.

Common applications for foam tapes include:

- Cushioning and padding

- Insulations

- Gaskets

- Seals

The right type of foam tape can improve both the visual appeal and functional performance of various household and industrial products. Foam tapes come in two major categories: open cell and closed cell. It is important to know the differences between the materials in open cell and closed cell foam tapes to ensure appropriate selection of the right tape for your application.

Foam Tape Materials and Structure

The cell structure of the materials used to make open cell foam tapes are porous enough to allow air, fine particles, and water to pass through. Conversely, the materials used for making closed cell foam tapes have a closed cell structure that does not allow the passage of air, partical matter, and water.

Open Cell Foam

Open cell foam tape is typically made from EPDM rubber, polyurethane, or PVC/Nitrile, which are all airy and lightweight—these materials weigh about ½ to ¾ pounds per cubic foot. The low density of these materials gives them a high expansion/contraction capacity, which makes it easier to package and transport them. Open cell foams are resistant to molds, trap particulate matter like dust, and have good soundproofing characteristics.

Closed Cell Foam

Closed cell foam tape is typically made from EVA foam, polyethylene foam, neoprene foam, PVC/Nitrile foam rubber, or SBR foam rubber. Their closed cell structure makes these materials tough and dense, with densities falling in the 2–3 pounds per cubic foot range.

Closed cell foam tape is typically made from EVA foam, polyethylene foam, neoprene foam, PVC/Nitrile foam rubber, or SBR foam rubber. Their closed cell structure makes these materials tough and dense, with densities falling in the 2–3 pounds per cubic foot range.

The higher density makes closed cell foam more expensive, but they are strong, have a higher R-value, and feature better resistances to air and moisture. As such, they are excellent for protective packaging and soundproofing applications.

Foam Tape Resistance Capabilities: Open Vs. Closed

While open cell foam tapes are resistant to oxygen and have a high degree of flexibility and dexterity, they don’t offer much in terms of resistance to water or moisture vapors. Closed cell foam tape offers a variety of beneficial features, such as excellent leak resistance, good soundproofing and shock capabilities, and high resistances to heat, moisture, and vapors.

Open vs. Closed Foam Tape Applications

Open cell foam tapes offer an ideal solution for indoor soundproofing applications. However, their tendency to absorb and retain water makes them poorly suited for outdoor construction or building applications.

Closed cell foam tapes better suited for these projects. Other applications that use closed cell foam tapes include:

- Aerospace and aircraft projects

- HVAC systems

- Medical disposables

- Shock absorption

- Thermal insulation

The better insulation characteristics of closed cell foam tapes come from the structure of their cells. The cells have robust walls that make it more rigid and trap a large volume of air. This makes the material sturdier, providing better insulation.

Foam Tapes from NADCO

NADCO Tapes & Labels, Inc., designs and manufactures open and closed cell foam tapes. We supply double-sided and single-sided foam tapes for a variety of critical industries, such as the aerospace and medical sectors. NADCO can customize the design and properties of these tapes to suit different applications.

Our downloadable eBook offers guidance for selecting the right foam tapes for specific use cases. Our subject matter experts are also available to our customers for consultations. Contact us today to learn about NADCO’s products and services, and how we can help you in selecting the right foam tape for your project.

Adhesive Tapes: Solutions for Your Appliances

Adhesive tape consists of two main parts: a backing material and an adhesive film. Together, these components join two separate objects without the use of mechanical fasteners such as nails or screws.

When used in appliance manufacturing operations, adhesive tape enables industry professionals to streamline their manufacturing processes. In part, this simplification is due to the fact that adhesive tape accommodates lower working temperatures. Additionally, adhesive tape causes little to no damage to the surface of the product, allowing for a more polished finish.

From noise reduction to insulation—and everything in between—finding the right tape for your project can provide significant benefits. The following blog post gives a brief overview of the role that adhesive tapes play in the appliance industry, including outlining typical functions and types available.

Using Adhesive Tape in Appliances

In the appliance industry, adhesive tapes serve a number of different functions. In addition to acting as an alternative to mechanical fasteners for assembly applications, they also:

In the appliance industry, adhesive tapes serve a number of different functions. In addition to acting as an alternative to mechanical fasteners for assembly applications, they also:

- Protect sensitive and critical components from moisture and other contaminants

- Prevent damage to the surface of a product during production and transportation operations

- Provide acoustic and thermal insulation for sections exposed to high noise and temperature differentials

Depending on the needs of the application, there are several specific adhesive tapes to choose from, such as:

- Thermal conductive acrylic foam tape: provides thermal insulation for appliances

- Open cell foam tape: dampens the noise and vibrations from loud machinery

- PVC adhesive tape: used to mark or bundle various wires and cables to increase organization

- Waterproof seam sealing tape: prevents moisture and other contaminants from entering an enclosure

Adhesive Tapes for Domestic Appliances

Adhesive tapes serve as a fastening solution for both industrial and domestic (i.e., consumer) appliances. For example, industry professionals may utilize them to provide noise reduction for dryers, deliver surface protection, and assemble or attach parts. Some of the leading tapes used in these types of applications are:

Cell Foam Tape

While cell foam tape is primarily used for noise and vibration reduction in loud appliances, it also has several other uses, such as:

- Stabilizing refrigerator coils

- Bonding windows in oven doors

- Securing HVAC insulation

- Attaching membrane switches to microwaves

Vinyl Electrical Tape

Vinyl electrical tape is ideal for providing insulation. More specifically, it should be used alongside materials that conduct electricity, such as wires.

Aluminum Foil Tape

Aluminum foil tape features pressure-sensitive adhesive made from rubber. Due to the design of the adhesive, it can be used to protect irregular surfaces as it easily conforms to the surface to form a solid barrier against contaminants. It is suitable for a variety of applications, including use on the seams and joints of fiberglass and aluminum-backed duct board, in refrigeration systems, and as protection for thermal insulation.

Custom Adhesive Tape Solutions From NADCO

At NADCO Tapes & Labels, we specialize in providing custom labeling and adhesive solutions. Our pressure-sensitive adhesive tapes are available with a broad selection of customization options to suit virtually any customer need, including in appliance manufacturing applications.

From initial design to delivery of a finished product, our creative team works tirelessly to ensure that every customer receives the perfect adhesive tape for their unique project. Contact us today to learn more about what we have to offer.

How Adhesives Are Keeping Your Car Together

Flexible, powerful bonding solutions play an essential role in the manufacturing processes for vehicles. By relying on adhesives instead of other joining methods, manufacturers produce cars that are lighter, more fuel-efficient, and made up of more varied components. Using adhesives also leads to fewer emissions produced throughout the process.

Use of Adhesives in the Automotive Industry

Adhesives are on the rise in manufacturing processes compared to traditional joining techniques like welding. In some vehicles, there are up to forty pounds of adhesive materials. This weight is just a fraction of the rivets, welding agents, and other heavy metal equipment that could be used in traditional processes and designs.

By exchanging metal parts for adhesives, manufacturers can create cars that weigh less. Through that single change, cars offer a higher mileage rating, while manufacturers lower their environmental footprint.

One popular adhesive material is double-sided bonding tape. Its benefits include:

- Shear strength:This prevents the bonded materials from failing in shear or sliding apart in a direction parallel to stress. Double-sided adhesive tape has shear strength that prevents most failures or gradual slippage.

- Strong adhesion:This material sticks to a variety of surfaces without failing. It can bind together two unlike materials, such as plastics and metals, which cannot be welded together.

- Low weight:Its lighter weight means it can replace several pounds of welding and joining materials while still offering superior performance.

- Temperature resistance:Both commercial and consumer vehicles face a wide range of internal and environmental temperatures. Adhesives can withstand low and high temperatures without losing strength once the bond is set.

- Biodegradability:Just as car manufacturers face increased pressure to create fuel-efficient vehicles, they also must consider other environmental costs. Many adhesive products, such as double-sided bonding tape, is biodegradable.

Due to these advantages, manufacturers prefer using adhesives compared to welding. Welding adds significant weight to the vehicle and is an expensive process. Welding stations require a lot of specialized equipment and raw materials, and the costs for the process in terms of time and labor is high. Adhesives, on the other hand, can quickly be applied whether it’s by a team of manufacturers or automated lines.

The Future of Adhesive Tapes in the Automotive Industry

While automotive adhesives can be used during any stage of the manufacturing process, they are most commonly applied during the body in white (BIW) state, which is when the sheet metal body of the car is being pieced together. According to the Automotive Adhesives Market forecast in 2015, this stage of the process represents the greatest use of adhesives. Further, this area of application will be the highest growing area of adhesives usage through 2021.

While automotive adhesives can be used during any stage of the manufacturing process, they are most commonly applied during the body in white (BIW) state, which is when the sheet metal body of the car is being pieced together. According to the Automotive Adhesives Market forecast in 2015, this stage of the process represents the greatest use of adhesives. Further, this area of application will be the highest growing area of adhesives usage through 2021.

Automotive manufacturers prefer to use double-sided tapes and other adhesives during the BIW stage because of the characteristics listed above, especially the reduction in weight. As double-sided adhesives become stronger and more diverse, they are quickly replacing most applications of metal fasteners and pins. They also allow for more varied designs and innovations. Adhesives designers and manufacturers will play a critical role in the evolution of vehicles as they create, support, and test specialized adhesives.

Because adhesives can bond unlike materials, demand for mild steel will also continue to drop in favor of low-alloy steels that no longer need to withstand welding and heat distortion. Other materials that will grow more popular include aluminum, magnesium, and plastics. These changes will become more apparent throughout the next decade as vehicle composition changes to support demands for lower weight, greater fuel efficiency, and smarter design.

Contact NADCO Tapes & Labels, Inc. Today to Receive a Quote

Double-sided tapes and other adhesives have advantages that traditional welding and fastening techniques can’t compete with. As automotive manufacturers develop designs and improvements based on adhesives’ lightweight and durable characteristics, cars will evolve into more disruptive designs.

To learn more about our double-sided tapes and other adhesives for your next manufacturing project, contact NADCO today.

Flexible, powerful bonding solutions play an essential role in the manufacturing processes for vehicles. By relying on adhesives instead of other joining methods, manufacturers produce cars that are lighter, more fuel-efficient, and made up of more varied components. Using adhesives also leads to fewer emissions produced throughout the process.

The Top 5 Benefits of Pressure Sensitive Labels

Pressure-sensitive labels (PSLs) consist of sheets or films coated on one side with an adhesive substance that is activated by pressure. These labels offer an advantage over other types as the pressure-sensitive adhesive does not require exposure to water or a solvent, allowing for quicker and easier application to a wide range of surfaces.

Due to the simplicity and versatility of their design, pressure-sensitive labels find use in a variety of consumer and retail applications, including on bottles, cans, jars, tapes, and electronic products. Selecting and using pressure-sensitive labels for your product(s) offers you a host of benefits. The top five benefits are:

#1 – Convenience

Pressure-sensitive labels withstand and maintain their integrity in a variety of environmental conditions, such as heat, cold, humid, wet, and dry environments. This quality makes them very attractive to producers that are looking for both ease of application and reliability.

The pre-application of adhesive on pressure-sensitive labels reduces the number of steps required for the labels’ application. As they don’t need the application of heat or exposure to a solvent to work effectively, they are also more readily and easily placed and applied on objects, including ones that do not respond well to heat or solvents.

Moreover, depending on the requirements of their application, different adhesives can be used to manufacture the pressure-sensitive label, allowing for permanent or temporary label application.

#2 – Ease of Use

Pressure-sensitive labels can adhere to virtually any material surface, including:

- Polyolefin-based

- Rubberized

- Dusty or contaminated

- Rough surfaces

- Humid or wet

Once their functionality or usefulness has played out, pressure-sensitive labels offer the additional benefit of being easily disposable as they contain minimal amounts of volatile compounds.

#3 – Wide Options to Choose From

Pressure-sensitive labels are available with a wide selection of customization options.

Adhesive Options

Depending on the requirements for the end product, the labels are applied with a variety of adhesives, including ones that that are:

- Permanent, semi-temporary, or temporary

- Heat or cold resistant

- Moisture resistant

- Anti-microbial

Substrate Material Options

Substrate Material Options

The substrate layer of the label is also available in a number of different materials, including:

Design Options

Once the substrate and adhesive substances are chosen, the finished pressure-sensitive label can also be fully customized with colors, patterns, textures, and designs, such as:

- Clear

- Metallic

- Glossy

- Matte

- Textured

- Wood grain

- Custom graphics and artwork

Overall, these labels provide a high level of customization in both their functional and aesthetic properties, making them suitable for consumer industries, including the beauty and cosmetics market.

#4 – Environmentally Friendly

Pressure-sensitive labels are more eco-friendly than other labels that require separate adhesive or solvent application. Compared to solvent-based labels, PSLs have minimal amounts of volatile compounds which can have adverse effects on the environment, and, compared to water-based labels, they require water to manufacture.

Pressure-sensitive labels are more eco-friendly than other labels that require separate adhesive or solvent application. Compared to solvent-based labels, PSLs have minimal amounts of volatile compounds which can have adverse effects on the environment, and, compared to water-based labels, they require water to manufacture.

#5 – Profitability

Pressure-sensitive labels provide manufacturers with an effective and economical solution for their labeling applications. The versatility and ease of use of these labels make them suitable for a broader range of manufactured products, minimizing the number of different labels required in inventory for everyday operations.

Customized pressure-sensitive labels are available at low costs with a variety of options for the adhesive, substrate, and design. Generally, customization of these labels results in high quality rendered products suitable for use in consumer and retail applications.

Additionally, as the adhesive is already on the label, less time is required for applying adhesive or activators, changing labels, and cleaning up spilled substances. By optimizing these label application operations, facilities experience improved overall productivity and, consequently, profitability.

Partner with NADCO for Your Label Needs

At NADCO Tapes & Labels, Inc., we are an industry leader in the production of custom printed pressure-sensitive labels suitable for countless industrial and commercial applications, including:

- Product identification

- Branding

- Decoration

- Safety and information

We offer several different printing methods that can be tailored to meet your project requirements. These methods include:

- Flexographic printing

- 4-color processing

- Spot printing (up to 7 colors)

- Short-run digital printing

Request a Quote today to learn more about how NADCO can meet and exceed the expectations of your next project! Our pressure-sensitive labels provide the functional and aesthetic qualities required for your products.