3M™ Dual Lock™ Reclosable Fasteners With Acrylic Adhesive Tape

3M™ Dual Lock™ Reclosable Fasteners are innovative and durable fastening solutions engineered to withstand repeated closing and reopening actions. Featuring interlocking mushroom-shaped heads that possess a tensile strength five times that of hook and loop products, these fasteners’ mated strips slide past one another, snapping into place to create a secure closure that still allows them to peel apart as needed.

3M™ Dual Lock™ Reclosable Fasteners are innovative and durable fastening solutions engineered to withstand repeated closing and reopening actions. Featuring interlocking mushroom-shaped heads that possess a tensile strength five times that of hook and loop products, these fasteners’ mated strips slide past one another, snapping into place to create a secure closure that still allows them to peel apart as needed.

Strong enough to tolerate up to 1,000 openings and closings before experiencing half of the original tensile strength, these fasteners are also resistant to moisture exposure, high and low temperatures, and UV radiation. Simple to install, maintain, and clean, these products are capable of reducing vibration. They are available in standard, low-profile, and pressure-sensitive adhesive options to fit the needs of your specific application.

From mounting automotive accessories to creating quick-release access panels, 3M™ Dual Lock™ Reclosable Fastener strips are ideal for securing items to a range of surface materials. Read on to learn more about the 3M Dual Lock from NADCO® Tapes & Labels, Inc.

Applications

Designed with versatility in mind, 3M™ Dual Lock™ Reclosable Fastener strips are an excellent solution for the following attachment and quick-release applications:

- Interior panel attachments. 3M™ Dual Lock™ Reclosable Fasteners are ideal for installing interior panels with the capability to later release them for maintenance in:

- Passenger conveyances like elevators, buses, or railcars

- Emergency vehicles like ambulances

- Shipping vessels and watercraft

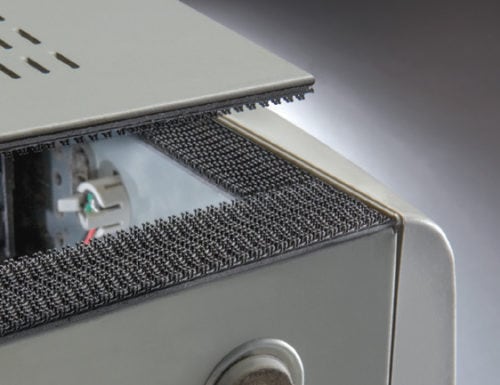

- Removable access panels. 3M™ Dual Lock™ Reclosable Fasteners keep electrical or mechanical components covered while ensuring easy access when you need it for:

- Electrical junction enclosures

- Control boxes for equipment like elevators

- Recessed lights

- Valves for natural gas and water

- Mobile mounting. To attach devices to windshields, dashboards, and other vehicular surfaces, 3M™ Dual Lock™ Reclosable Fasteners provide a secure mounting solution for:

- Sensors, GPS tracking devices, and other such electronic equipment

- Recreational vehicle and motorcycle components

- Display and signage. Lastly, these fasteners are flexible in that they allow for interchangeable signs, displays, and assemblies for retail or informational purposes. Examples include:

- Kiosks

- Free-standing displays

- Point-of-sale (POS) attachments

- Price tags for retail products

- Placards

Application Guide

To optimize the bonding process, you should thoroughly clean and properly treat substrates before applying 3M™ Dual Lock™ Reclosable Fasteners. For most substrates, you can achieve this with a solution of half isopropyl alcohol (IPA) and half water. However, additional surface treatments may be necessary for:

- Promoting adhesion. For difficult-to-bond materials like plastics or painted substrates, a priming treatment can enhance a surface’s capability for adhesion.

- Preparing porous surfaces or unique materials. Porous or fibrous substrates like concrete, wood, and particleboard require proper sealing to create a unified surface for adhesion. Also, substrates with unique material properties typically require specific surface preparation techniques to optimize adhesion. This is true for glass or glass-like surfaces, plastics and rubbers with plasticizers or other migrating materials, and copper or copper alloys.

- Removing heavy oils. Substrates covered in heavy oils or grease generally require treatment with a solvent-based cleaner or degreaser prior to using the IPA/water cleaning solution.

- Removing heavy dirt or oxidation byproducts. To remove excess dirt or the byproducts of oxidation, certain substrates may require an abrasion treatment before cleaning with the IPA/water mixture to support optimal adhesion.

Once you have properly prepared a substrate, you can easily apply the 3M™ Dual Lock™ Reclosable Fasteners by following these steps:

- Peel the protective liner away from each strip of the fastening system to expose the adhesive backing

- Use a roller to facilitate a strong bond, attaching each individual strip to the substrates you wish to join

- Firmly press the substrates together until the heads interlock

Alternatively, you can peel one strip’s protective liner away, attaching the mated strip to one of the substrate surfaces with a roller. Next, expose the adhesive backing by peeling away the other liner. Press it into the second surface, attaching it to the adhesive and completing the bond. You can then peel the two surfaces apart, as needed.

Reclosable Fastener Solutions at NADCO

3M™ Dual Lock™ Reclosable Fasteners provide a superior alternative to conventional mechanical fasteners in applications that require quick-release fastening or repeated openings and closings. At NADCO, we excel in delivering innovative standard and custom adhesive solutions, offering an extensive array of pressure-sensitive tapes and other products that address specific fastening challenges. We offer 3M™ fasteners as part of our product line because the Dual Lock™ Reclosable Fasteners with acrylic adhesive tape bond to a range of substrates, making them suitable for diverse surface types and applications.

To learn more about the fastener selection at NADCO, please contact us or request a quote today.